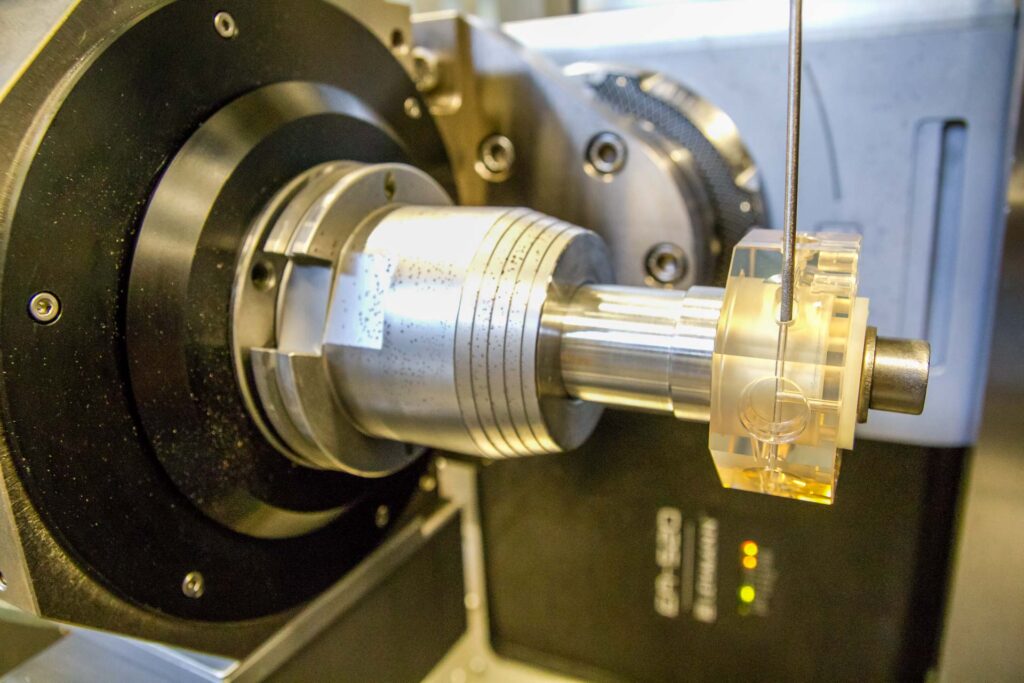

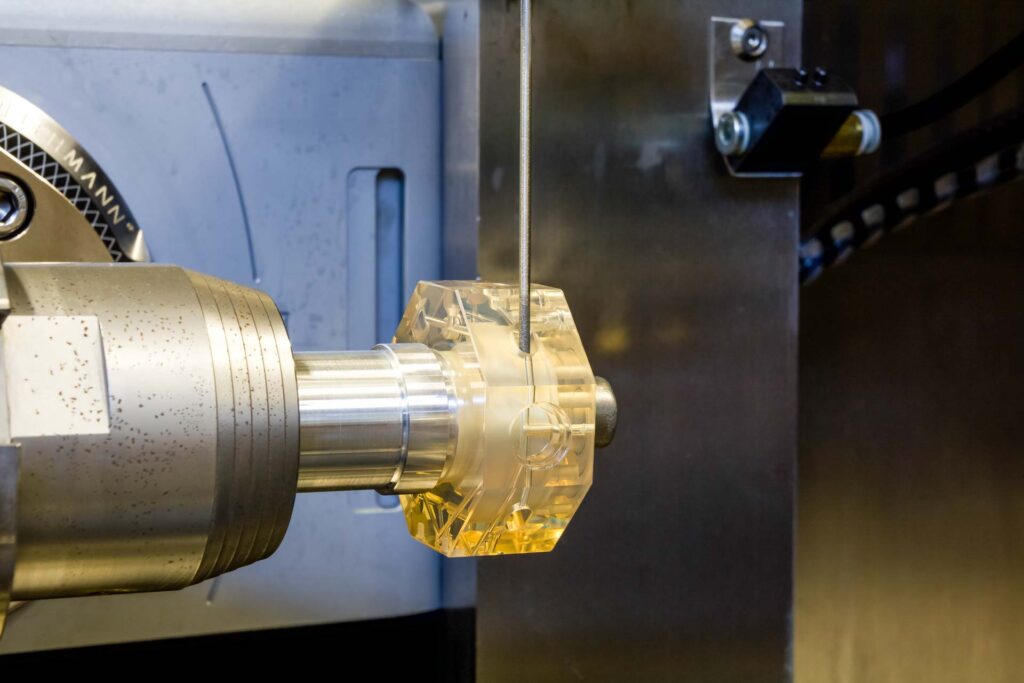

The MC50 micro grinding machine is a high-precision 5-axis machining center. All axes are controlled directly via linear and torque motors. The machine is ideal for grinding and micro milling. Direct drives, optical measuring systems and versatile spindle options enable efficient and precise machining. The optional ultrasonic technology is particularly suitable for grinding brittle-hard materials such as glass and ceramics. The machining area is made entirely of stainless steel.

MC50 – Compact performance with maximum precision

The MC50 micro grinding machine is a powerful and compact 5-axis machining center that has been specially developed for high-precision applications. With this machine, we offer an innovative solution in the field of 5-axis precision machining with a minimal footprint. With direct drives and a robust design, the MC50 micro grinding machine achieves maximum precision in demanding manufacturing processes. Motor spindles with HSK E50 or E32 with up to 60,000 rpm enable flexible material processing, while the optional ultrasonic technology is particularly optimized for hard-brittle materials such as glass and ceramics. The intelligent control and versatile automation options make this machine the ideal choice for the precision optics, precision mechanics and ceramics industries.

Main features:

- Compact design: 5-axis machining on a footprint of just 1.78 m²

- Direct drives: linear motors and torque motors for maximum precision

- Versatile spindles: HSK E50 & HSK E32 with up to 60,000 rpm

- Ultrasonic machining: with inductive energy transfer for HSK E50

- Automatic tool changer: space for up to 18 tools

- High-precision measuring systems: Integrated glass scales for exact repeatability

- Corrosion protection: Complete machining area in stainless steel design

- Control system: B&R CNC or Siemens ONE