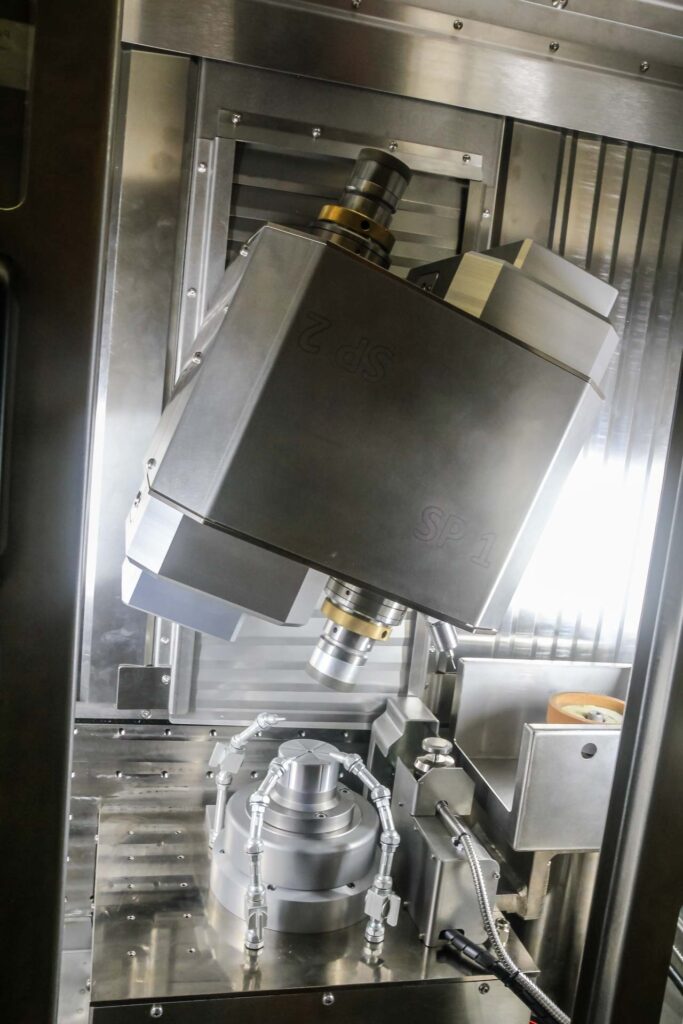

The CG 321V lens grinding machine with 2 grinding spindles offers maximum precision when grinding spherical lenses. The grinding spindles can be positioned in a parallel or 180° arrangement. Both spindles are equipped with internal cooling. 3D probe and dressing spindle are optionally available.

CG 321V – Highest precision for grinding spherical lenses

The CG 321V 2-spindle lens grinding machine is a versatile solution for the high-precision machining of lenses. With this machine, dama technologies ag offers modern technology in the field of flat / spherical grinding. The machine has an X-, Z- and B-axis . The two grinding spindles in a 180° arrangement enable flexible processing options with automatic dressing of the grinding wheels. A parallel arrangement of the two grinding wheels offers high productivity. The HMI of the B&R control system is very intuitive. The machine can be automated with a robot cell.

Main features:

- Grinding spindles: Two grinding spindles in 180° or parallel arrangement

- CNC control: Simple dialogs and G-code programming possible

- Internal cooling: Optimum flushing of the sanding process

- Workpiece clamping: Integrated rotary feed-through for vacuum or pneumatic clamping

- 3D probe: Automatic grinding wheel compensation

- Robust design: High stability and precision

- Can be automated: Prepared for the attachment of a standardized robot cell