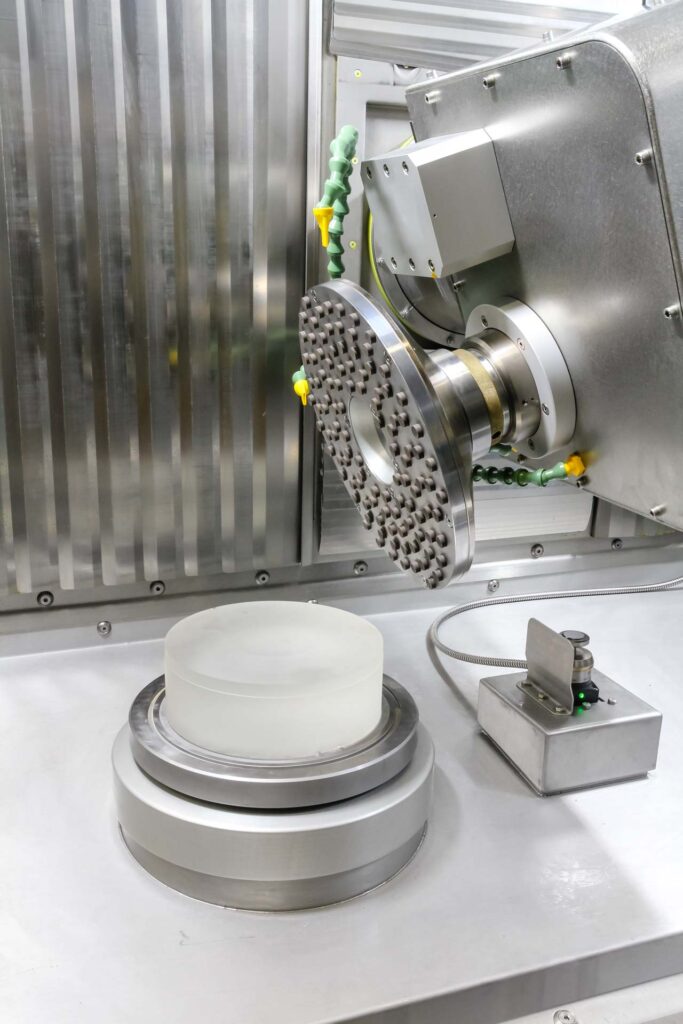

The SSM surface and spherical grinding machine enables high-precision grinding of flat and spherical components. With up to 5 axes and a powerful CNC control system, it offers maximum flexibility. Thanks to its modular design, it can be used for ultra-fine grinding, asphere and prism grinding.

SSM – Versatile grinding for maximum precision

The SSM surface and spherical grinding machine has a modular design and can be individually configured according to customer requirements. From 1- to 5-axis design, with 1 or 2 spindles, workpiece and tool probe, dressing spindle as well as vacuum or magnetic clamping, everything is possible. The linear axes are located outside the machining area and are optimally protected against contamination. This guarantees a long service life and low maintenance requirements. The machines have a large processing door with an upward opening for crane loading.

Main features:

- Flexible axis configuration: Up to 5 axes for versatile machining options

- CNC control: Intuitive dialogs and free G-code programming

- Grinding spindle: programmable from 500-4000 rpm for grinding wheels up to Ø 300 mm

- Workpiece spindle with vacuum and/or magnetic clamping: Up to Ø 550 mm

- Process control: Automatic feed control depending on the spindle power

- Robust design: Complete machining area in stainless steel design

- Can be automated: Optional solutions for fully automated production